With the holidays just around the corner, the most stressful days on the logistics calendar are almost here. Could autonomous solutions like Shelf -To-Person solve some of these problems while benefitting employees and sustainability at the same time?

The answer to the question is yes. In a fast-paced environment like supply chain, there are many things to keep in mind when operating a warehouse and creating a sustainable and pleasant atmosphere.

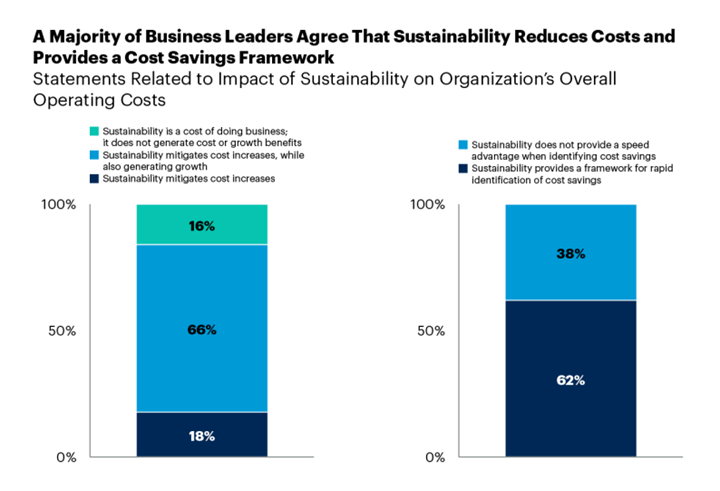

Today’s warehouse administrators not only need to think about business operations, but they also need to think long-term regarding sustainability. According to the Gartner Sustainability Opportunities, Risk and Technologies Survey 2022, more than 60% of organizations agree that sustainability initiatives can help to reduce cost and provide a framework for cost savings and at, the same time, generate growth.

CEVA and Geek+ working together to create a better working environment

CEVA is working with Geek+ at the Grobbendonk (Belgium) warehouse to provide automation operations for a famous footwear brand. The Shelf-To-Person solutions deployed have not only offered an improvement of efficiency and accuracy, but also a more ergonomic working environment for the operators.

The warehouse is also working with 1700 solar panels on the roof of each of the 5 halls which allows CEVA to expect a production of 3230 kWp to power lighting and air conditioning. This helps to reduce carbon emissions by adopting new technologies at this facility.

Sustainability is one of the pillars for Geek+. Geek+ is delighted to help our customers fulfill and exceed their sustainability goals. With the use of these Shelf-To-Person robots and other solutions deployed worldwide, we have saved 140,000 tons of carbon emissions and 16 million KwH in energy in 2022.

Operations in an automated warehouse run 24 hour / 7 days of the week. Robots can replace high energy consuming logistics equipment, and reduce the use of electricity, lighting, and air-conditioning in the warehouse as robots operate in dark areas. In addition, the robots themselves have low power consumption, and their battery life expectancy is 60% higher than the industry average.

Another point that is not always highlighted when speaking about energy consumption, is data cloud deployment. This reduces the usage of a physical server; it is easy to scale up or down the server resources depending on production needs and help the efficiency for saving all the data regarding the warehouse management system.

Improving the working environment

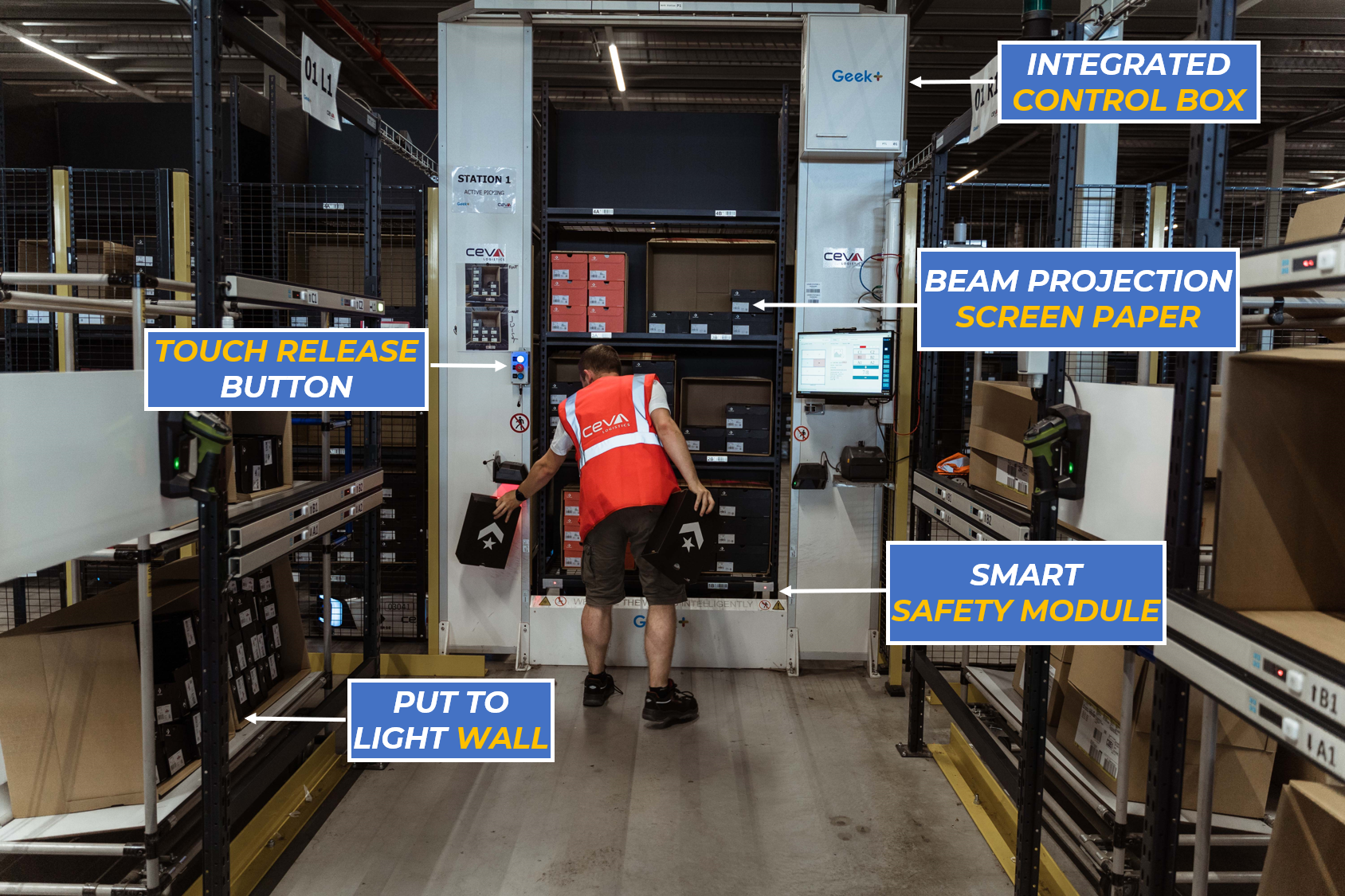

Safety has also improved in the era of automated picking and operators, for example, now enjoy better working conditions. New work stations, where operators do inbound and outbound operations, have numerous safety measures put in place. What does this working station consist of?

- Integrated control box: Inside this box it can be placed industrial control computers, electronic label controllers, projector controllers, etc. Therefore, it can save workstation space and facilitating unified management and security control.

- Beam projection screen paper: Special material projection screen paper to increase the clarity of the protection display and to show the number of picks.

- Touch release button: For single-sided picking of shelves to complete the release of AMR, no user interface operation is required, and the position can be changed according to the site layout to avoid ineffective movement of personnel.

- Smart Safety Module: Includes modular system emergency stop and safety grating for the safety of warehouse operators

Ergonomic improvements for employees

Improving the working place is top priority for CEVA Logistics and Geek+ regarding the Grobbendonk project. Therefore, Geek+ has designed a solution for CEVA’s employee which improves picking efficiency with the implementation of a put to light wall (P2L). This wall enables operators to move all the finished orders boxes in one go with the wall moving the boxes manually to the packing area. Instead of going one-by-one like traditional operations, the operator can handle 4 walls with 6 boxes each at the same working station full of goods inside. Also, the P2L is a very intuitive and quick tool to use for the operators while picking because once they scan the good, the operator just must see the screener and the light which signposts where to put the good.

Unlocking innovation potential is one of the main objectives that both CEVA and Geek+ have in mind when developing a project together. This wall is continuously being improved by both teams according to operators' preferences and suggestions. For example, we have recently improved the inclination of the shelves’ levels towards inside. Therefore, the boxes are better placed for picking them and for the different travels over the P800 robots. The mobile shelves which transport the goods are designed to put full cartons into the shelves directly. This improves the operator’s position while managing boxes for the outbound operation.

Worker happiness is a pursuit that we try to make happen every day at the warehouse. At Geek+, we work every day to fulfill our customer’s objectives. We will continue in this pursuit, using our technological advancements to make lives better in the workplace and beyond.