Warehouse digitalization is not just a trending keyword over the recent years, but is in fact becoming an unadulterated necessity for businesses to maintain a competitive edge and meet the rising demands for agility and accuracy.

Pain points of traditional warehouses

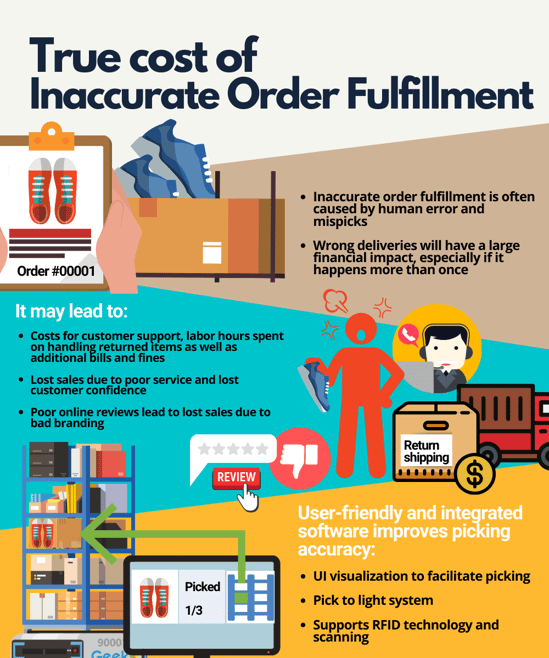

1. Endless Mispick by Labour

Before delving further, it would be handy to first elucidate the need for warehouse digitalization i.e. why traditional warehouses do not fit the bill anymore. Firstly, traditional warehouses are non-automated, which means the completion of warehouse operations rely heavily on manual labour. Manual labour presents the risk of human error, which may impede picking accuracy and increase inventory count errors. This incurs secondary costs – a single mispick can cost $22 and an average company losses $390,000 annually due to mispicks.

2. Minimum Efficiency

Moreover, given soaring demands and fluctuating business needs, there is a limit on the level of efficiency humans can render and this translates to a cap in picking rates. The training and experience of a human staff also comes into play here – compared to a seasoned professional, an inexperienced worker may potentially take a longer time to fulfil the task and risk making more mistakes as well.

(Read more: True cost of labor)

3. Labour Misallocation

Additionally, traditional warehouses also face the challenge of poor labour allocation. The inability to successfully determine the number of employees needed in a given time will result in a dramatic deviation from warehouse labour management productivity. This creates lulls and peaks in worker performance and efficiency, and can potentially contribute to the rise of labour costs. Concurrently, customer service levels may drop as a result from tired and inefficient workers.

4. Excess Inventory

The problem of overstocking is a real problem for traditional warehouses as well. According to John Larkin, most U.S. based retailers have $1.43 worth of inventory for every $1 in sales. This seems inevitable since warehouse managers may not always account for current stock levels accurately. At the same time, to prevent out-of-stock scenarios, additional inventory are often brought in, on top of existing inventory. Overall, this can translate to a considerable amount of tied-up working capital and contribute to increased warehouse rental space and thereby, cost.

Benefits of AI in warehouse digitalization

In view of the inefficiencies of traditional warehouses, warehouse digitalization open the window to AI algorithms and a host of applications from automating processes to tracking real-time location of SKUs. By automating and accelerating warehouse processes, accuracy is also enhanced and workers are enabled to carry out routine operations faster than ever. With today’s business demand for fast time-to-value, this benefit is irrefutable.

Moreover, real-time synchronization, where AI algorithms can sync inventory databases with billing systems and financial data, greatly boosts the overall efficiency and transparency of the entire supply chain. Exact stock quantities and conditions of available stock can be easily retrieved, which eliminates stock misplacement and facilitates forecasting demand and planning supply. Warehouse space management can also be augmented through better space utilization, optimal allocation and redistribution of assets.

Practical applications of AI

Geek+ recognises the value of intelligent AI algorithms to build core competence for sustainable competitive advantage and has been working hard at the Geek+ AI research centre to develop robust algorithms suited for robotic intelligence and multi-robot collaboration.

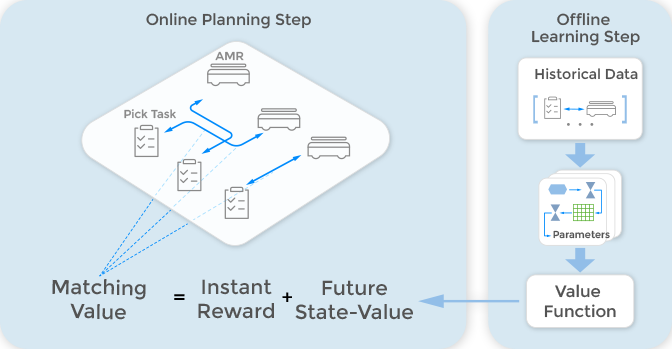

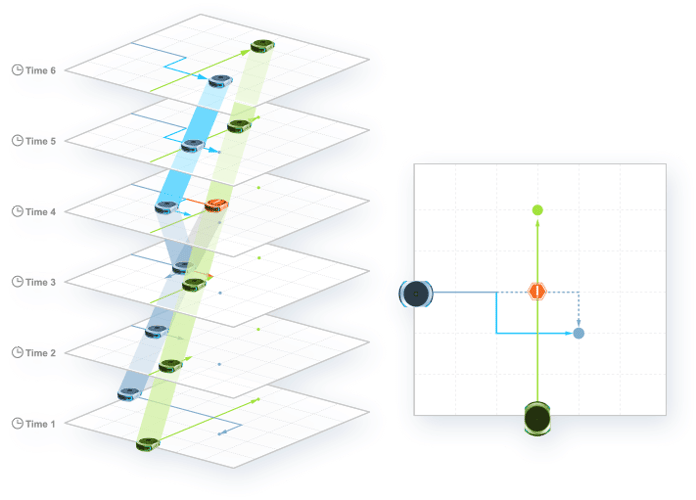

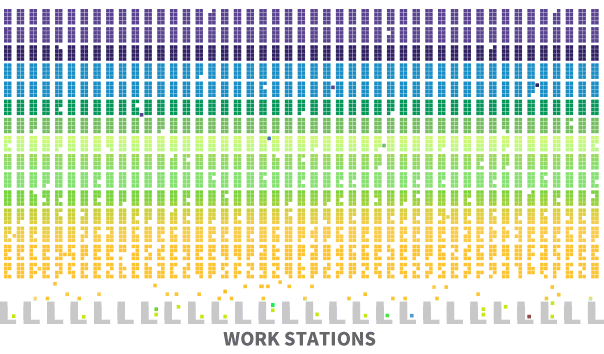

Firstly, these algorithms can be used to facilitate task matching, where shelves are paired with mobile robots to optimize the delegation of tasks in warehouses. Secondly, AI can be applied in collaborative path planning. Simply put, this helps to ensure that mobile robots travel to their stipulated destination in the shortest time possible while ensuring safe obstacle avoidance. This is relevant to another application of AI – shelf adjustment, where shelves likely to be transported are computed and mobile robots handling the tasks adjust the shelves to the most suitable position in the warehouse, so as to minimize their overall travel distance and maximize efficiency.

(Task matching)

(Path planning)

(Shelf Adjustment: The blocks with yellow color represent the high-hit shelves)

(Shelf Adjustment: The blocks with yellow color represent the high-hit shelves)

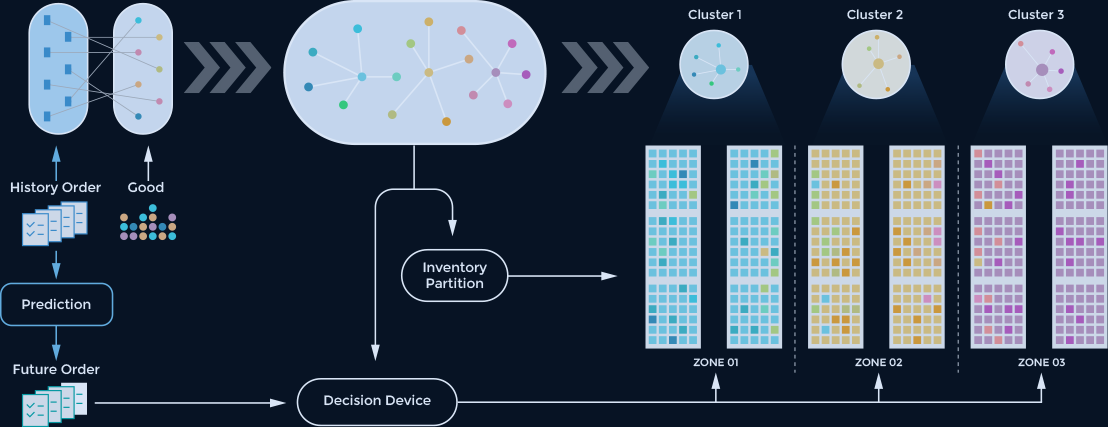

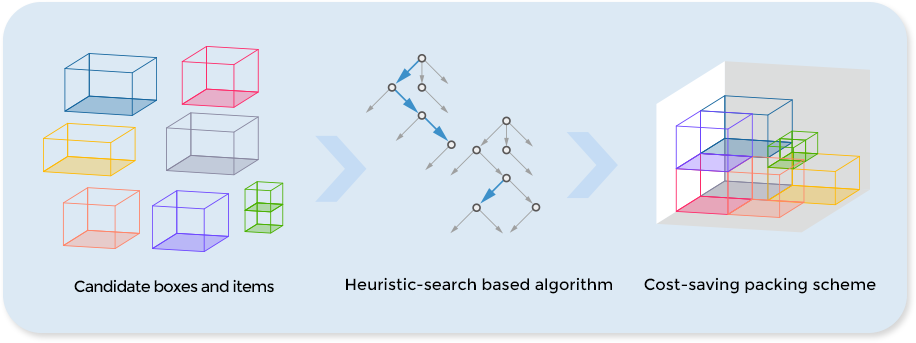

Additionally, order grouping is another domain that can be enhanced by AI. By mining and analysing massive historical order data, feature extraction, association analysis and unsupervised clustering can be attained. The result is phenomenal - not only can future orders be predicted and combined for efficient processing, inventory can also be partitioned accordingly based on different clusters. Another application of AI algorithms is 3D bin packing. Based on volumetric information of ordered goods, the algorithms recommend the most appropriate box size. This would be extremely helpful in keeping the cost of packaging materials to a minimum, thereby improving packaging efficiency.

(Order grouping)

(3D bin packing)

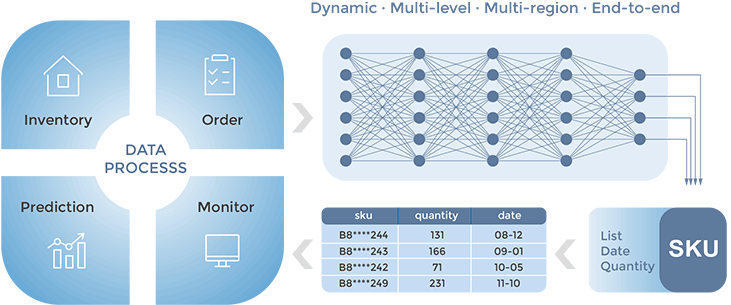

Last but not least, smart replenishment can be realized with AI algorithms. Based on real-time monitoring of warehouse stock status and order sales, a deep neural network is employed to generate multi-level and multi-area replenishment plans. As such, supply chain inefficiencies such as the bullwhip effect can be circumvented whilst improving replenishment accuracy.

All of the aforementioned applications of AI would go a long way in improving efficiency and reducing operation costs for its users. Notably, Geek+ algorithms can be customized according to the unique business requirements of each client, and supports local software package invocation as well as other deployment modes. Since the the investment return cycle Is shortened for customers, business benefits for each customer can be maximized in the swiftest and most convenient way.

In closing, with multiple driving forces such as the proliferation of e-commerce, increase in manpower and rental costs and rising demand for rapid order fulfillment, it is clear that the digital transformation of warehouses will continue surging in the years to come. The future lies in digitalized warehousing and it is crucial that warehouses should start to scale up in order to gain the upper hand.

Stay tuned to our upcoming article where we are going to follow up on the role of cloud-based warehouse management in warehouse digitalization.